How does the country’s nuclear deterrence system help make Goodyear tires? And how do Goodyear tires help improve nuclear deterrence?

Designing the Perfect Tire

Aerodynamicists and engine builders may argue the point, but I believe the most complex part of a car is the tire. Rubber is a fascinating material all by itself. It stretches, hardens, wears, and changes irreversibly with temperature.

But tires aren’t just rubber. Over 40 chemical components go into making a tire, as shown in the photo from Goodyear below.

Add to all the possibilities in materials even more possibilities in construction:

- tire diameter and width

- sidewall width and stiffness

- tread pattern (or lack of same)

There are so many variables, it’s impossible to make and test every possible combination. So how does a tire engineer figure out what to try first?

If that’s not enough of a problem, once you think you’ve made the perfect tire, you have to prove it.

Tire Testing

Goodyear uses a Flat Trac machine to test tires. The machine’s arm holds a tire against a rolling belt, which simulates the road surface. It’s like a dynamometer, but for a single tire.

And now we have even more parameters to change!

- tire pressure

- mounting

- camber

- yaw

- temperature

- load

- surface type

- speed

A Flat Trac system can simulate hard cornering and quick stops, or it can just put 20,000 miles on a tire in a day. Goodyear has Flat Tracs for everything from car tires to huge airplane tires. The video below shows the Flat Trac in action.

But running such a machine is time consuming and expensive. Just the energy bill is huge. Not to mention that you still have to design and produce a limited run of each tire you want to test.

Limits Stimulate Innovation

NASCAR limits everything from on-track testing to wind-tunnel time to save teams money. As a result, drivers spend more time in increasingly advanced driving simulatiors. Aerodynamicists spent more time with computational fluid dynamics simulations.

So why isn’t Goodyear designing their tires in a computer?

They are. But they’re not doing it alone. Accurate simulations of something as complex as a tire, over a wide range of conditions, requires sophisticated code and large computers.

Sandia National Laboratories is one of 17 national laboratories, each with its own mission and unique facilities. Along with Los Alamos and Lawrence Livermore National Labs, Sandia’s mission is to maintain the country’s nuclear deterrence program. Sandia is responsible for the non-nuclear parts of nuclear weapons. That includes everything from missiles to the trucks that move nuclear assets.

If you think NASCAR is a tough sanctioning body, just try working for the United States government. It demands that the country’s nuclear weapons always work when lawfully called upon, but never work under any other conditions. Those conditions may include sitting for decades in humidity and temperature extremes.

And, like NASCAR, the government has a no-testing policy. The last U.S. nuclear detonation was in September, 1992. That meant the scientists and engineers had to develop sophisticated computer codes to model very complicated phenomena.

Their purview encompasses nuclear detonations to the impact of corrosion to the consequences of truck carrying nuclear waste getting into an accident.

Materials Modeling

Sandia’s computer code (called Sierra Mechanics) models the behavior of a wide range of materials because their mission requires them to deal with all those materials.

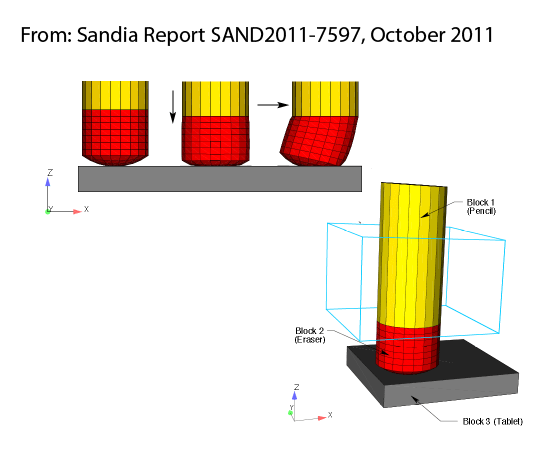

It’s simple to erase a mistake with a pencil eraser, but it’s far less simple to model it. The eraser changes shape when you press down. It bends when you pull it to one side. But some parts bend more than others, so you can’t just treat the eraser as one unit.

Sierra Mechanics divides the eraser into small elements (as shown below) and then analyzes each element’s behavior.

Now imagine doing the same thing with a tire. We’re talking so many of those little elements that you need the third fastest supercomputer in the world.

Michael Skroch is Sandia’s Manager of Simulation Modeling Services. I spoke with Skroch and Dr. Gregory Bunting, a computational physicist at Sandia to learn more about this program.

Goodyear has worked with Sandia since 1992. (Goodyear does pay Sandia to do the work.) One of the partnership’s big successes is Goodyear’s Assurance TripleTred. The TripleTred, with its three-part tread compound, is a relative of the multi-tread race tire Goodyear introduced in 2013.

Bunting points out that they can’t just deal with the macroscopic level, like an eraser or a tire. They also simulate materials at the molecular-level. For example, they look at how the bonding between rubber and carbon black changes the material’s stiffness or elasticity.

With the code they’ve developed, they can do a large part the tire-designing process on a computer instead of in the physical world. That saves time and money. Having the ability to investigate all those options also produces a better tire.

But the team wanted to go beyond just designing tires on a computer. They wanted to be able to test tires, too.

The Virtual Flat Trac

Their latest success is simulating the entire Flat Trac testing process. The Virtual Flat Trac reduces dependence on physical machines and speeds up the time from concept to market.

The team can design a tire on the computer, and then run that tire through the test program. The program generates the same type data (for example: heat and wear) that a physical test would produce. The results can guide new ideas or help select which tires should be made for physical testing.

Simulations Don’t Do Everything

Just as NASCAR engineers tell us, though, Skroch and Bunting agree that computer simulation lessens, but doesn’t eliminate the need for real-life testing. Sandia also runs physical tests of materials and structures to ensure that their code is accurate.

I’ve told you before about the SAFER barrier tests and the challenge of getting a driverless car up to race speed. Sandia had to get a fully loaded semi-truck up to highway speed so they could crash it into one of its Mobile Guardian Transporters, which are used to move nuclear components.

They used rockets.

Skroch noted that the Sandia collaboration focuses primarily on consumer tires, but the programs will work just as well for race tires. You should expect to eventually see this technology coming to a race track near you.

How Goodyear Tires Help National Security

It’s clear how this collaboration benefits Goodyear. But what does Sandia get out of it (other than money)?

In other words: Why tires?

First, Skroch noted that Goodyear’s recent acquisition of Cooper Tires makes them the only American-owned tire and rubber company. Helping Goodyear be competitive in the global marketplace is good for the country.

Secondly, the Virtual Flat Trac project was complex. A lot of new code had to be generated. But everything Sandia scientists learned and created gets folded back into the Sierra Mechanics program.

For example, Skroch says, their scientists and engineers might not spend as much time studying elastomers (like rubber) without the Goodyear relationship. But there are rubber-like materials in the nuclear stockpile. The knowledge generated by this collaboration also improves the reliability of the nuclear weapons that are Sandia’s primary priority.

Neither Skroch nor Bunting have gotten to a NASCAR race yet, but they did get to drive on Goodyear’s San Angelo, TX proving grounds. Skroch noted that a lot of what he learned on that visit are counter-intuitive. A good reminder, he said, to trust the science instead of your gut.

Many thanks to Michael Baker at Sandia for facilitating the interview.

Related Links

Please help me publish my next book!

The Physics of NASCAR is 15 years old. One component in getting a book deal is a healthy subscriber list. I promise not to send more than two emails per month and will never sell your information to anyone.

Discover more from Building Speed

Subscribe to get the latest posts sent to your email.

Be the first to comment